There was a time when Australia’s economy “rode the sheep’s back”.

The selective breeding of Merino ewes resulted in sheep that adapted well to the arid interior of Australia and produced wool that appealed to the mills of England.

(Source: National Film and Sound Archive of Australia)

This post, about wool, has been inspired by Paol Soren’s recent story titled “The Sale”. Without his encouragement I would never have thought to have written it. He feels my time in the wool industry is an experience worth sharing . . . I hope some of you agree . . . so here goes.

It has been many decades since England was the main customer for Australian merino wool. These days, the major markets are China – which bought $2.417 billion in 2015/16 – followed by India ($216 million) and Italy ($160 million). Other players include Thailand, Malaysia, and the Czech Republic (!).

(Sales figures sourced from Wool Producers Australia website).

Walcha Agricultural Show 2014 Prize-Winning Merino Fleece in greasy (raw) state. Photo Gwen Wilson

It’s strange to reminisce that when I first started my shipping career in the early 70s China wasn’t even a market, but by the mid-1990s I was working for a wool trader who specialised in selling wool tops to China.

* Wool Tops – The greasy wool has been scoured (washed), combed and sorted to the point where it is ready for spinning.

In order to export wool anywhere, step one is “shear your sheep”. This requires such a range of people that even backpackers are working in the woolshed these days. But I won’t go into detail about the process or this post will be too long. You can get the idea from this song with accompanying video. (Rolf Harris’ diction and explanation is excellent, hope those of you who realise his reputation is no longer as excellent will forgive my use of it).

The fleece is baled at the shed, using a wool press as illustrated in Paol’s post. Sometimes, those bales are already destined for a buyer. In the video you can see some marked for Bradford Mills (must be an old video 🙂 🙂 ).

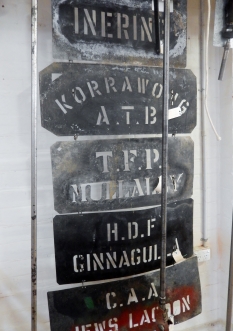

Wool Growers’ Stencils. Photo Gwen Wilson

Usually though, the bales are stencilled with the wool grower’s mark and transported to a capital city where they are put into the hands of a wool broker. The broker either direct sells them, or, more commonly, puts them up for auction. Over 85% of the annual clip is sold through an “open cry” auction.

Before being listed in the auction catalogue, the bale is “cored”. A cylindrical instrument is pushed deep into the bale to withdraw a sample which is then tested the certify the “yield, fibre diameter, vegetable matter content, staple length and staple strength”.

Much to my disappointment, I was never invited to accompany my employer to the auctions. Which is perhaps just as well, because by nature traders are risk takers. I frequently had to draw up contracts for sale when we hadn’t even purchased the wool. Had I been by my boss’ side I would have been too anxious about whether we would be the successful bidder – or indeed, even whether the correct specification of wool was available at that sale!

If the trader had done the “right” thing and purchased bales before he had a buyer they would be sent into storage for me to stock control. This could be all around Australia depending on where the auction had taken place. Transport-in, storage, then transport-out add cost, which is one of the reasons for my boss taking a calculated risk and selling before buying.

Wool Bales. Source: Department of Primary Industries, Australia

Once sold, the bales were shipped to destination in containers. Bales are big and bulky and consume lots of expensive freight space, so this is where the wool dump comes in.

Wool Dumping: “The process of compressing two bales (double dump) or three bales (tri-pack) of greasy wool into the approximate size of one bale and restraining them with steel bands for shipping/transport.” (Source: AWTA Ltd).

I frequently visited the wool dump near Sydney, and that is where Paol Soren’s post sent my memory neurons into over-drive. How well I remember the “twang” that precedes the dumped bales about to blow its steel straps. Decapitation material.

A dump press at one of AWH’s storage centres with tri-packed bales in foreground (Picture: AWH Pty Ltd)

Note the danger sign in the above photo. This photo comes from a 2015 magazine article. “My” wool dump of twenty years before used equipment that was nowhere near as flash. (GG 2022 My original post had photos of a Two into One, and a Three into One wool dump, but the images to have expired, and quick look on the internet did not reveal any current photos.)

From the point of purchase at auction until payment was received from the buyer, the wool was under my control. The dumped wool was packed into containers, transferred to the wharf and onto the ship. All sales were contracted under a Letter of Credit, an ancient process of bank-guaranteed payment subject to everything being tickety-boo, mostly the paperwork at this stage. It was a nit-picking process – even a misplaced comma could incite delays from a buyer who was trying to squirm out of his contract. Anyway, I won’t bore you with all that!

One of my responsibilities was to negotiate the shipping freight rates and so I was very interested to read the (copyright protected) article referenced at the end of this blog.

The article is exploring the effect that China’s trade imbalance is having on freight rates from Australia to China. More shipments are coming in to Australia than are going out. This means the empty containers stockpile in Australia when they are needed in China. Having subsequently worked for a Japanese shipping line and being responsible for container control (as well as several other departments 🙂 ) I am well acquainted with the problem.

So if you had to make a choice between shipping empty containers at your own expense, or dropping the freight rate – which decision do you think shipping companies will make? Well, it’s not always that straightforward, because shipping lines are usually part of a consortium, and all must agree. There are also other reasons you wouldn’t drop your freight sales price too low, but it seems that in some cases the rate is now so low that from the exporter’s perspective it is cost-effective to skip the dumping process (which costs them) and load the bales in “as-is” condition, even if that means more containers are required.

Which takes me back to the early 80s when I was working for a bathroom-ware manufacturer. Sea-freight rates between Australia and New Zealand were maintained at an artificially high price by a right of operation, called cabotage, which prevented competition. Meanwhile, airfreight rates were dropping to an incredibly low rate. It became cheaper for us to airfreight plastic cisterns rather than pack them in shipping containers. We were flying them over by several semi-trailer loads at a time (not sending the truck of course LOL).

Pan-American Cargo was still flying then, using the all-cargo 747 with the nose cone which would swing open for the freight to be loaded straight in. On one occasion my shipment needed a good portion of the space, as plastic cisterns are light but bulky. Co-incidentally, another exporter was consigning ping-pong balls. When the Pan-Am despatchers calculated payload and saw how little fuel was required, they thought one of us had made a mistake. The phones ran hot all afternoon checking and re-checking our weights and measures until they were fully satisfied with their calculations. Airfreight exporters are charged by weight or volume, whichever is the greater, using a calculation of 167kg to the cubic metre. So we two exporters paid volumetric weight, and PanAm took on much less fuel than usual – so I think their balance sheet had a nice leg-up that day. Unfortunately, not enough of those days to keep them in business.

I’d love to include a photo of the plane, but again, I’m not sure about copyright. This is a link if you are interested.

It was a gorgeous plane, and very suited to its purpose. The (standardised size) cargo pallets slid off the hydraulic lift and were sent along guide runners until they reached rollers dotted across the floor, then they would be turned into their final position and lashed down. Everything lined up with no wasted space, and freight could be loaded almost to the skin of the aircraft. The pilots had limited space though, mostly the cockpit and a little “kitchenette” behind them. The upside was not having passengers to worry about 🙂

Gosh! It’s starting to sound as if I still miss my days in the freight industry. No wonder I call this blog The Reluctant Retiree 🙂

*********

Copyright Credit for magazine article:

Why Australia now exports more farm bales than dumped wool

By James Nason, 26 February 2015

The amount of wool being put through the “dumping” process in Australia prior to export has shrunk by almost 50 percent in the past decade, reflecting the attractive “back-freight” rates now available in surplus containers being returned to China.

https://www.sheepcentral.com/why-aus-now-exports-more-farm-bales-than-dumped-wool/

Well this was a really interesting post. I clicked on the links and learnt lots. But I remember when we moved to ‘the Bush’ in the 50s that the shearing shed was build before the stone house was built. Before that we lived in the house made with stringy bark gum trees and lined with super bags. A great read – lots of good memories.

LikeLiked by 1 person

I’ve often read of your early life and marvelled at the bush and construction that you called home. Quite the adventure!

LikeLike

That was very interesting, Gwen.

LikeLiked by 1 person

Thank you Don.

LikeLike

I learnt quite a few things I didn’t know before in your post! When my father left school in the 1920s he started out training as a wool classer. He gave up what would have been a perfectly respectable occupation to try a series of unsuccessful ventures until his death at the age of 53. Your experiences with wool were further along the line and much later in history of course but I was keen to read it to see where our wool goes now and how it gets there.

LikeLiked by 2 people

In my experience, wool classers were well respected and knowledgeable. But! It may have been a career that had your family on the move a bit.

I didn’t update the article to our current export figures. I wonder what the trade is with China now. I didn’t hear they put on any sanctions as with other parts of our export trade such a wine, barley, coal, etc

LikeLike

Reblogged this on The Reluctant Retiree and commented:

For reasons best known to the Happiness Engineers at WordPress, Paol Soren’s most recent post threw up a link to an older one of mine. Some of the links were broken and I updated them with alternatives, so if the wording does not make complete sense, that is the reason. Also a couple of the links appear beyond redemption, but I guess the gist of it still makes sense. Be warned – This post is heavy on detail, which may not suit all readers.

LikeLike

Have a memorable ANZAC Day, Gwen!!!

LikeLiked by 1 person

Thank you so much. I must, must, MUST get to bed soon if I am to be up for the dawn service. Although I’ll skip the gunfire breakfast (mainly rum).

LikeLiked by 2 people

Aussie Emu said he’ll be going to gunfire breakfast but will be in bed by 3. 🙂

LikeLiked by 1 person

Probably the same for us. We’ve had the dawn service and been to breakfast. We’ll watch some of the main Sydney march on the TV and then there should be a fly past from our local aviation society. Next up a bit of modified two-up in our lounge, plus a few drinks all round. By mid-afternoon there’ll be a few poppy naps happening for sure.

LikeLiked by 1 person

Sounds like a wonderful day all-around.

LikeLiked by 1 person

Gabby One, that was very interesting indeed. I can just hear that “twang” when the bales were released, somewhat like a plump lady releasing that corset!

LikeLiked by 1 person

Nice analogy. (Except you don’t want to be in the path of that flying steel).

LikeLike

Pingback: Postcard for Gwendoline. – Paol Soren

Great explanation of what looks like a complicated ‘freight’ dance including as you say negotiations, cabotage and collusion. I can see from all this why nowadays there are difficulties in attempting to factor possible climate change charges into freight costs. 🙁

LikeLiked by 2 people

Yes, it is a fact-based industry and it is difficult to factor in the cost of imponderables. Having said that, shipping lines are always alert to waste, and for some time have been experimenting with returning wind-power to their vessels and thus reducing the cost of bunker oil.

LikeLiked by 1 person

Oh wow – wind power, that is news to me. I think that would be very interesting and has a hint of romance about it too, but I am guessing it’s not full sails. 😁

LikeLiked by 1 person

Yes, I should have clarified that they are wind “assisted” concepts. There are at least seven ideas wafting around with various appearances. My former employer NYK has a 2030 target.

LikeLiked by 1 person

Fascinating. I read this with great interest (which explains why I never catch up with my blog emails).

LikeLiked by 2 people

I’m glad – and relieved – you liked it. And I know the feeling of trying to keep up with all the blog reading and responding. So much of interest out there, but it does all take time!

LikeLiked by 1 person

Theres nothing is as exciting as being in the woolsheds whilst the shearers are going flat stick; that’s what interests me most

LikeLiked by 1 person

A very good post! Why wouldn’t you think we’d be interested, Gwen? This is a production process most of us have never come in contact with, we just see the finished product. I have seen on TV the people shearing, but that’s about it. I know I learned a lot here..

LikeLiked by 2 people

Paol (aka John) said as much i.e. that most people don’t know how this works.

Whereas I was fearful I would only be spruiking what was already common knowledge. I’m so glad you gleaned something from it.

LikeLiked by 1 person

Why don’t governments explain to the people why freight prices are the way they are. You made a lot of this clear to me, even though I worked ,for a short while, with AML&F who were in the wool business.

I’m very glad you posted this. If you put your mind to it I’m sure there is a lot more you could add.

LikeLiked by 2 people

Ahhh freight rates. That heady mix of supply and demand . . . and collusion. And all the government of the day wanted to do was blame high prices on the wharfies. They wanted to break unions at any cost, starting with the MUA. We’ve just had the 20 year anniversary of the Patricks Waterfront Dispute, which saw my husband locked out of his workplace for more than three months. In case you need a reminder . . .

https://en.wikipedia.org/wiki/1998_Australian_waterfront_dispute

Yes, I could have gone on with more detail in this post – on, and on . . . and on. But I was scared I’d bore the pants off everyone 🙂

AML&F hey? Now there’s blast from the past. I note the Gunnedah branch had a 150 anniversary in 2013. And here’s a link to another reunion you might like to keep your eye on: https://www.stockandland.com.au/story/4407871/amlf-last-muster-reunion

It says they call it the “Last Muster Reunion” because so many have either deceased or are in the CALL-UP PEN. Sounds as if you did well to get out of THAT industry.

Not that I can I boast much better. I still have a reference from my time as a motel receptionist in 1973 – from DALGETYS – saying how well I looked after their people whenever they came to town 🙂

LikeLiked by 2 people

Magic post Gwen. A part of our history that is too easily forgotten.

LikeLiked by 1 person

A typically excellent piece. Paol did well to get you on the job. I forgive you the video – it is still historically useful

LikeLiked by 1 person

Thank you so much Derrick. Your approbation is greatly appreciated. And mercifully, Rolf Harris is not the author of the musical piece, merely one of its many interpreters.

LikeLiked by 1 person